| Copyright 2012 LiteBrake Tech. All Rights Reserved |

| Steel Clad Aluminum Brake |

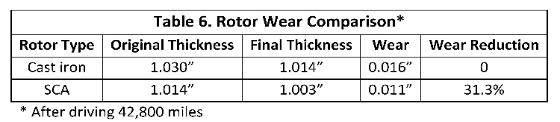

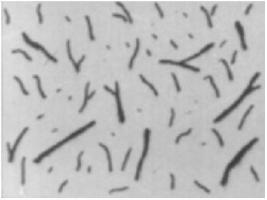

| Rotor Wear Rate Reduction and Expected Service Life The SCA rotor has demonstrated significant wear rate reduction without compromise of friction coefficient in dynamometer tests and a long term road test as presented in Tables 5 and 6. It is not difficult to understand the reason. FIG 19 is a typical microstructure of cast iron material. It consists of flake graphite and iron (i.e. very low carbon steel) matrix. The graphite has very low mechanical strength, therefore, the cast iron can be viewed as a low carbon steel with lot of flake porosity. If solid without porosity, the low carbon steel should have better wear resistance than the “porous low carbon steel”. If a steel with carbon content similar to that of a cast iron matrix is selected, the steel could present similar friction coefficient as the cast iron matrix. The entrapped graphite is a kind of solid lubricant. Therefore, it lowers the friction coefficient of cast iron matrix. In other words, the selected steel shows both higher wear resistance and higher friction coefficient. |

| Lighter, Cooler, Better and Greener |

| LiteBrake Tech, LLC |

| SCA Brake |

| TM |